Magnetic

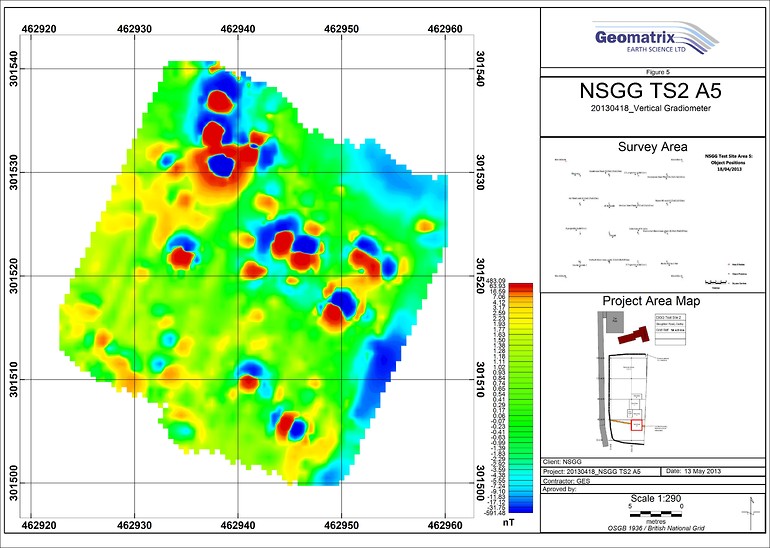

In a magnetic survey, spatial variations in the Earth’s magnetic field are measured, typically caused by the presence of magnetic materials such as iron and iron oxides in the subsurface. These variations can be detected using magnetometers, which measure the intensity of the magnetic field at specific locations.

Magnetic surveying has long been used in industries like mineral and oil exploration, where it helps detect anomalies related to underground deposits of magnetic minerals. More recently, it has become an essential tool for a wide range of industrial and environmental applications, including:

- Detection of abandoned mine shafts and adits: Magnetic surveys can identify disturbances in the Earth’s magnetic field caused by voids or cavities left by old mining activities.

- Locating man-made targets: The method can be used to find underground structures such as brick-lined shafts, underground storage tanks, and buried steel drums.

- Identification of unexploded ordnance (UXO): Magnetic surveys help detect the presence of metallic objects, making them crucial in areas that might have unexploded bombs or shells.

- Archaeological surveys: High-resolution magnetic data can be used to locate buried features such as foundations, walls, and other structures that might not be visible on the surface. Advantages of Magnetic Surveying:

- Speed and Cost-Effectiveness: Magnetic surveys can cover large areas quickly and at a low cost, making them ideal for initial surveys in exploration and environmental assessments.

- Minimal Data Corrections: The method typically requires fewer corrections to the field data compared to other geophysical techniques.

- High Sensitivity and Resolution: Modern magnetometers offer high resolution and sensitivity, making them suitable for portable gradiometers, and allowing them to be mounted on vehicles or used in airborne sensor arrays for large-scale surveys.